Industries

Industries we serve in and around Milwaukee, Wisconsin

Construction

Overhead material handling equipment in construction

Not all construction companies build their houses and buildings onsite. In recent years, many have begun building and assembling components in a factory or warehouse, which they transport to the job site. Known as prefabrication or modular construction, it’s a trend that’s expected to reshape the construction industry by streamlining projects.

With prefabrication, a construction company assembles components, either completely or partially, offsite rather than onsite. Once assembled, the components are transported to the location of the project, at which point workers will make the final touches. Prefabrication is used in a variety of manufacturing-related sectors. In construction, however, it’s particularly beneficial because it allows construction companies to finish projects more quickly and efficiently.

The actual construction of the structure is assembled within a factory setting which will allow for overhead cranes to maneuver sections efficiently and safely. The use of material handling will allow companies to run leaner and in turn have a quicker turn-around time. The advantage of building in a controlled environment will give modular construction companies the advantage over the traditional on-site stick building.

Energy

The energy industry contains all the industries involved in the production and sale of energy. That includes manufacturing, refining, extraction, and distribution. With modern society consuming more energy than ever the energy industry is very important almost everywhere in the world.

In its entirety, the energy industry contains:

- electrical power industry;

- gas industry;

- petroleum industry;

- coal industry;

- renewable energy industry;

- coal industry.

Energy gives us light, powers our electronic devices, makes it possible to watch all these shows, etc. At work, people depend on energy because it powers the machines that manufacture the services or goods we work with.

No industry has the bigger impact in the world than the oil and gas industry. It provides us with light, mobility, heat, and it makes our lives better — it enables us to travel, study in the evenings, use our smartphones and PCs, etc. And all of this is a part of the energy industry.

Cranes in the energy industry is key to allowing utility companies to move, repair or replace generating equipment. In the fossil fuel industry, the use of cranes can make simple and safe work in moving heavy containers or equipment.

Save Money,

Eliminate down time

Quality is and always has been, our number one priority. We have built our reputation by offering products with an uncompromising commitment to quality, reliability and customer service.

Steel industry cranes and applications

Iron and steel foundries require high reliability, durability and safety of load handling, therefore, the crane and its parts are developed to meet the highest standards. Cranes used in this environment need to be designed to transport hot liquid steel in harsh environments with extremely high temperatures putting significant stress on the crane and its components.

There are several things to identify when selecting the correct overhead crane for you selecting the right overhead crane for your application:

- The type of crane you need (single girder or double girder)

- Rated load capacity

- Span

- Lifting height

- Lifting speed

- Duty cycle

- Control mode (remote control or cabin control)

- Power source

- Do you need a runway? If it is, what is the length of the runway?

- Other special requirements

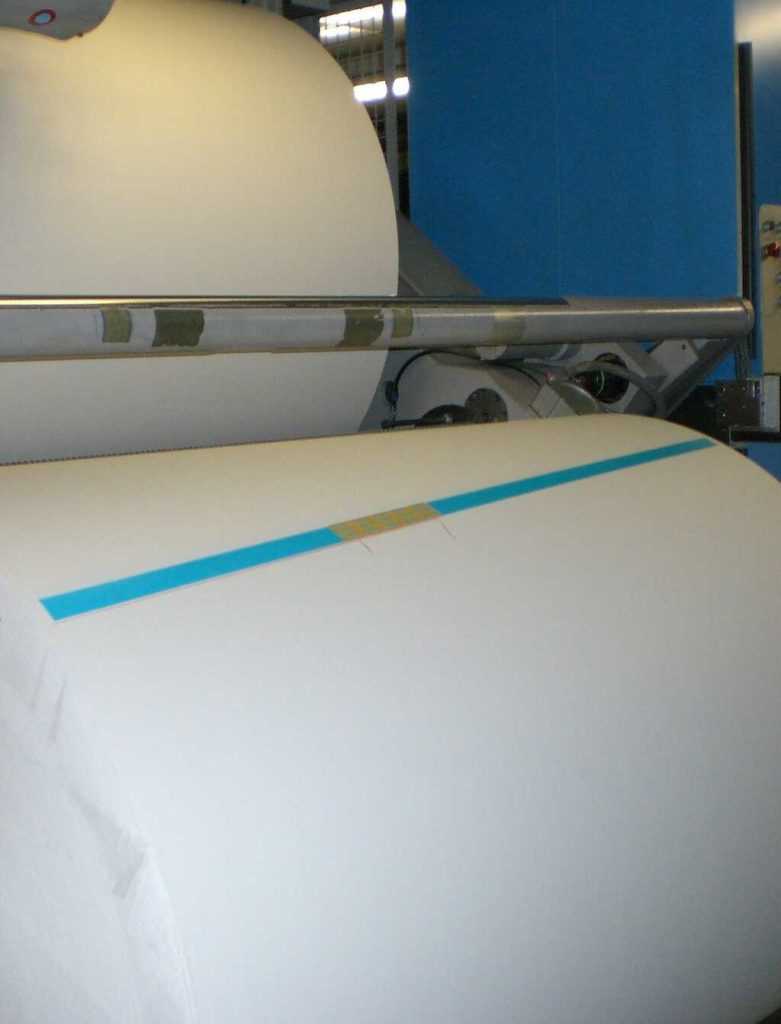

Paper cranes in industries and applications

Cranes used in the pulp and paper industry are an integral part of the production process and maintenance. There are several areas to consider when choosing the best crane for your use.

- Range of product use – Low capacity maintenance to automated systems for storage and retrieval

- Task of the crane – rotating spreader/beams, log grabs & paper, reel vacuum lifters

- Applications – wet, dry end, reel & roll handling, automatic shipping roll storage and intermediate roll storage, sheet cutters roll storage.

Cranes in paper factories must operate reliably and correctly around the clock as production downtimes cause high costs. The use of cranes for positioning paper reels weighing several tones precisely is one of the most demanding applications in crane technology.

Manufacturing

Cranes in manufacturing and application

Metal Manufacturing

Cranes are used for moving crucibles of molten ore or loading rolls of finished sheet. Metal workers require overhead cranes to handle the weight as well as the elements – metals at dangerous temperatures. Overhead cranes can do this work and help keep workers at a safe distance from dangerous materials. Specialized attachments such as C-hooks can help move spools of wire and foil, too.

Concrete Manufacturing

The concrete industry is neither small nor light. Workers need gantry cranes in the yard and bridge cranes in the factory to handle bagged premix or finished precast. Pouring architectural spans requires the power and control of an overhead crane.

Power Plants

Power plants are filled with working equipment that must remain functioning 24/7 avoiding downtime & blackouts. When a turbine or generator inside an active plant needs service, it must be removed and replaced with care. A precise bridge crane system is essential for this service.

Ship building

A wide-spanning heavy gantry crane is a must for building ship hulls. Ship hulls are massive and irregularly shaped. Moving heavy tools and parts around the inside of a slanted hull can be impossible without an overhead crane.

Plastic Injection Molding

The plastic fabrication industry involves heavy weights & high temperatures. Safety and precision demand a strong and agile system of overhead cranes. Elements to consider include – melted ingredients, raw materials, and finished products which must be handled with care and dexterity. This is where the need for overhead cranes comes in.

Automotive

Bridge cranes are ideal for auto assembly lines providing reliable movement of their product from station to station on its journey to completion. Gantry cranes can be used for auto repair for jobs such as pulling engines and lifting car bodies. Automation of these complex systems of machinery require a programmer to help operate and maintain the cranes.

Military / Government Cranes and APplications

Cranes for Military require special technical considerations. The equipment versions for military cranes may include the following, depending on requirements/applications:

- Rescue winches

- Towing hitches

- Tires with emergency features

- Emergency hydraulic controls

- Various load handling equipment

- Special containers for transporting special accessories

Crane solutions are available for transport, material handling and recovery for both wheeled & tracked vehicles in support of the widest variety of military projects and applications throughout the world. Loader cranes are suitable for mounting on all chassis types, e.g. for repair and maintenance applications, as a classical material handling crane, bridge-laying crane and recovery crane.